-

Mobile: +90 532 446 19 32

-

Phone: +90 312 385 60 34

-

EMAIL: fatih@goksualtyapi.com

What is sectional point repair:

The Sectional point repair process begins when a high velocity jettersis used to clear alldebris and foreign material out of the pipeline. CCTV inspectionis the next step. A videocamera must be used to determine the location and condition of the damaged pipeline. Anepoxy mixture is saturated into a mat composed of fiberglass and felt. Then, this mat iswrapped onto a bladder that is inserted into the sewer pipeline, to the exact damage location.The bladder is then inflated to the proper pressure level to couple the repair to the pipe. Thebladder is a “flow-through” which means it allows continual usage of the sewer. After theproper curing time (usually 2-3 hours), the bladder is deflated, and then removed endingthepoint repair process.

Göksu offers a No Dig, trenchless pipe rehabilitation as sectional pointrepair materials for small and large pipe diameters up to 1000 mm. Bycreating environmentally sound alternatives, An alternative to ‘dig andreplace’ methods, the Göksu product line challenges traditional pipe repairmethods as a ‘trenchless excavation’ that is an efficient, long-lastingsolution to repair many sectinal point repairs in one day.

Through this process, not only does our trenchless technology cure theinfiltration, but improves the performance of the storm or sewer system.

Göksu’s proactive approach provides a structural point repair within apipe. When compared to digging or lining an entire pipe, Göksu No Digsystem only repairs areas that require rehabilitation—saving time,investments, materials and hours of labor. Göksu materials is able toefficiently make multiple repairs, remain environmentally friendly and may only require as little as one factory trained installer by utilizing trenchlesstechnology. As infrastructure constantly requires maintenance, a pointrepair is the number one solution for structurally rehabilitating pipes,allowing customers to allocate their time, funds and resources elsewhere.

Packers:

Göksu offer many highly innovative and efficient solutions forsuccessful rehabilitations. Our product range includes, among others,rehabilitation packers, lock-off technologies or house-connections. Ourwell-proven products include furthermore rehabilitation packers forstraight lines and bendy-packers for curved lines. These packers areunique in the market. They are produced with unique material componentsand are extremely durable. Our rehabilitation packers help you torehabilitate the easy way.

Resin: Göksu resin is supplied in two parts – resin and waterglass –which are activated on mixing.Three formulations are available, Summer, Winter and Rapid, which givedifferent working times and speed of curing, to suit the ambienttemperature when being installed on site (see below). It should be notedthat colder temperatures will lengthen both working and cure times;higher temperatures will reduce both times.

Göksu resin is supplied in two parts – resin and waterglass – which are activated on mixing.

Three formulations are available, Summer, Winter and Rapid, which give different working times and speed of curing, to suit the ambient temperature when being installed on site (see below). It should be noted that colder temperatures will lengthen both working and cure times; higher temperatures will reduce both times.

The Benefits of Göksu resin include:

• High temperature resistance

• Excellent chemical resistance compared to all other pipe repair resins

• Water-glass based polysilicate resin for strength and flexibility due to unique cross-linked molecular formula

• Able to cure in the presence of water, for no washout during installation

• Excellent bonding properties to most materials

• Excellent migration properties between the resin and fibreglass mat, for consistent impregnation

• Non-flammable, so ideal for airports, hospitals, stations and other public places

• Non-hazardous and completely inert once mixed, so no transport or disposal problems

• Odourless, so ideal in confined spaces

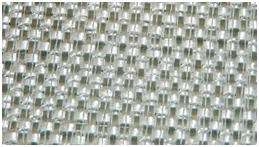

Fiberglass: High Quality fiberglases density 900 gr/m2 – 1400 gr/m2